The rapid development of the new energy industry in recent years has brought a large amount of supporting demand to the cooling tower industry. Wanxiang has become an excellent supplier to several leading new energy enterprises. We have established cooperative relationships with companies such as Huayou Cobalt, TCL Zhonghuan, Lishen Battery, Jinchuan Group, Nantong Ruixiang, and Ronghui Lithium for over 10 years.

Wanxiang is widely used in various scenarios in this field. In the manufacturing factories of ternary lithium cathode materials, lithium carbonate, lithium iron phosphate, lithium cobalt oxide, lithium hydroxide, lithium hexafluorophosphate, etc. in the entire lithium battery industry chain, as well as in the reduction furnaces, purification furnaces, single crystal furnaces, and photovoltaic module factories in the entire photovoltaic cell industry chain, Wanxiang provides comprehensive services for different water users with its rich experience in system design and engineering construction, relying on the advantages of product energy efficiency, anti scaling, anti freezing, and whole machine shipping.

For over a decade, our company has been providing cooling tower equipment and circulating water system technical services to Huayou Cobalt and its domestic and foreign subsidiaries. I have participated in over 60 project collaborations with more than ten of its subsidiaries, providing a total of over 200000 m ³/h of circulating water for cooling equipment. The projects have been implemented in Zhejiang, Guangxi, Hubei, Yunnan, Inner Mongolia, Tianjin, the Democratic Republic of Congo, Indonesia, and other places in China.

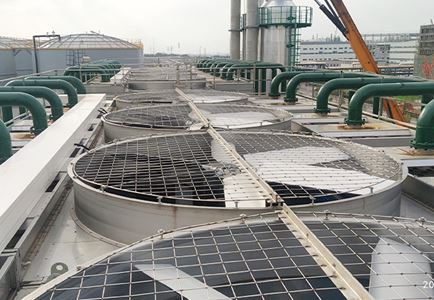

TCL Zhonghuan Co., Ltd. is a well-known comprehensive enterprise engaged in the production and operation of semiconductor materials, integrated circuits, and photovoltaics. Our company provides Rexroth cooling tower equipment and cooling circulating water system technical services for its Tianjin solar stacked tile module Phase I and Phase II smart factory and 25GW solar ultra-thin silicon single crystal smart factory. We have provided more than 40 fully steel dual condition cooling towers with a circulating water volume of over 25000m ³/h.

The world's largest ternary lithium cathode material base, our company participated in the design, production, and supply of its first, second, and third phase cooling tower projects. As of 2022, we have purchased nearly 157 sets of all stainless steel energy-saving cooling towers from our company, with a cooling circulation water volume of over 80000m ³/h.

Lishen Battery is a leading enterprise in the domestic lithium battery industry. This project aims to construct a 48GWh battery project with a leading scale in China. The first phase of the project will use 35 sets of our company's new energy-saving and water-saving steel cooling towers, with a cumulative circulating water volume of over 26000m ³/h. This product has made significant breakthroughs in high flow pipe layout and large-diameter suction.

Our company has provided intelligent operation design, all steel closed tower and auxiliary equipment supply, system construction and operation and maintenance for more than ten lithium battery positive electrode material projects in recent years. It is a benchmark project for the implementation of overall system solutions.

Ronghui General Lithium has cooperated with our company for more than 10 years. Many projects in Xizang, Jiujiang and Yichang have cooperated with our company. More than 10 years ago, it first used our company's high temperature patent cooling tower with Δ T>50 ℃. After the effect was successful, peer enterprises followed suit, and the same product has been purchased and used by nearly 10 enterprises.

Bamo Technology is a leading enterprise in the lithium electronic positive and negative electrode materials industry. In recent years, our company has provided multiple batches of all stainless steel energy-saving and water-saving open cooling towers and new closed cooling towers for the ammonia nitrogen wastewater resource treatment system engineering, air compression stations, refrigeration stations and other circulating water systems of its subsidiaries in Guangxi, Tianjin, Zhejiang and other projects.

Inner Mongolia Huajing New Materials Co., Ltd.'s lithium iron phosphate battery phase II project located in Ordos City is equipped with 24 sets of all steel closed cooling towers for the supporting air compression station, refrigeration station, and kiln circulating water system. The wind valve configured in this project has been specially designed (as shown in the picture), which better solves the problems of anti freezing, anti icing, and windproof willow catkins in the product. It can also adjust the air intake according to the working conditions. Compared with other brands in the first phase, the leading model is clear at a glance.